6. Lense-, bunkers- og ballastoperasjoner

Lense, bunkers- og ballastoperasjoner er i prinsippet knyttet til øvinger på simulator.

6.1 Lenseoperasjoner

I dette avsnittet skal vi se på lense-system og utstyr, som er underlagt strenge regler med sikte på å hindre oljeforurensning fra skip. Slike regler er fastlagt i internasjonale konvensjoner, herunder MARPOL. Da engelsk inngår som et sentralt krav til kompetanse for seilende maskinister, er dette avsnittet skrevet på engelsk.

6.1.1 MARPOL

To reduce pollution of the world`s coasts and waters by the shipping industry, a great number of laws, regulations set forth by the International Convention for the prevention of Pollution from ships, 1973, as modified by the protocol of 1978 (MARPOL 73/78 Annex 1), the Federal Water Pollution Control Act 1970 (FWPCA), and the Oil Pollution Act of 1990 (OPA 90).

Of greatest interest aboard the training ship are the regulations concerning the pumping of machinery bilge spaces. The law, as established by MARPOL 73/78 ANNEX 1, for ships of four hundred gross tons and above, defines permissible discharge of oil or oily waste from machinery space and fuel oil tank ballast water as follows:

- When the vessel is anywhere within a ”Special Area” which includes the entire Mediterranean Sea, Black Sea, Baltic Sea and Gulf Areas; No Discharge is permitted, except when:

1) The vessel is underway; and

2) The ship is operating an oil content monitor, oil separating or filtering device which will automatically stop discharging when the oil content of the effluent exceeds 15 parts per million (ppm); and

3) The oil content of the effluent without dilution does not exceed 15 ppm.

-

Outside of the “Special Areas”, and more than 12 nautical miles from land, the requirements are similar to the ones above except that the oil content of effluent discharge is relaxed to 100 ppm. In addition, discharge is permitted when the vessel is not underway, if the oil content of the effluent does not exceed 15 ppm.

-

Outside of the “Special Areas”, and less then12 nautical miles from land, No Discharge is permitted except when oil content of the effluent without dilution does not exceed 15 ppm.

The MARPOL regulations are more restrictive for oil tankers, and slightly more flexible for vessels of less than 400 gross tons. Before pumping bilge on your license, make sure you understand the law.

Illegal

It is no longer legal anywhere in the world to pump machinery space bilge directly overboard without going through some kind of oil content monitor that will automatically stop the discharge when the legal limit are exceeded!

In addition, U.S. laws prohibit any discharge which forms a sheen, sludge, film, or emulsion in U.S. territorial seas. Such seas are defined by the navigable waters, including river systems or into or open waters of the contiguous zone. The Department of Justice may prosecute an unlawful discharge or act in Federal District Court. Penalties set down by OPA 90 and the FWPCA are generally up to \$25,000 per day of violation or \$1,000 per barrel discharged. The master of the ship must immediately notify the nearest Coast Guard of en unlawful discharge and proceed in the cleanup. Gross negligence or willful misconduct could cause penalty costs to triple.

MARPOL regulations also require every vessel to maintain an Oil Record Book, where a permanent record of almost every handling of oil or oil waste is maintained.

For non-tanker vessels, the following operations must be recorded in the oil record book:

- Ballasting or cleaning of oil fuel tanks.

- Discharge of dirty ballast or cleaning water from oil fuel tanks.

- Collection and disposal of oil residues (sludge).

- Automatic and non-automatic discharge overboard or disposal otherwise of bilge water has accumulated in machinery spaces.

- Condition of oil discharge monitoring and control system (failures and repairs).

- Accidental or other exceptional discharge of oil.

- Bunkering of fuel or bulk lubricating oil.

- Additional operational procedures and General remarks.

The FWPCA and OPA 90 established additional regulations regarding the transfer of oil to or from the vessel. They state that no person may perform oil transfer operations unless he holds a valid license authorizing service on such vessels as master, mate or engineer, and has full knowledge of current oil transfer procedures that are maintained aboard the vessel.

During vessel-to-vessel transfer each tank vessel with a capacity of 250 or more barrels of cargo oil must have a means that enables continuous two way communication between the persons in charge of the transfer of operations of both vessels.

There must be onboard an emergency means to enable a person in charge of oil transfer operation to stop the flow of oil to a facility, another vessel or within the vessel. This may be the means of the pump control, quick acting actuated valve or an operating procedure. There must be adequate and protected lighting in the areas of oil transfer operation.

Responsibility

It is your responsibility as a marine engineer to know, understand and obey the law.

6.1.2 Bilge Well System (Lensesystem)

Bilge wells (Lensebrønner)

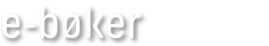

Figure 6.1.2.1 shows the Bilge Well System on MT Simulator.

The following Engine room bilge wells are included:

- Aft

- Fwd Port

- Fwd Stb

- Centre

A sludge tank and an incinerator are also part of the bilge system.

The bilge pump can take suction from any of the four bilge wells or from the sludge tank and discharge it to the bilge separator.

The Fwd Port engine room bilge well, in addition, receives possible overflow from the sludge tank and miscellaneous fresh water leakage/overflow from engine room systems.

The bilge wells cascade into one another as the bilge fills and overflows.

When the separator is in automatic operation it works on the Fwd Port bilge well. If the bilge separator is on for an excessive time an alarm will sound to indicate that there is a serious leakage.

Sludge tank (Slamtank)

The sludge tank receives drain from the following sources:

- HFO purifier sludge

- DO purifier sludge

- LO purifier sludge

- HFO settling tank 1 drain

- HFO settling tank 2 drain

The total water and oil input flows are summed up and displayed as two separate variables (oil, water) for convenience.

Oily return flow from the bilge water separator also enters the sludge tank.

Sludge can be discharged from the sludge tank to the incinerator or to shore reception facilities.

Figure 6.1.2.1 Bilge Wells (Lensebrønner)

6.1.3 Bilge Separator (Lensevann separator)

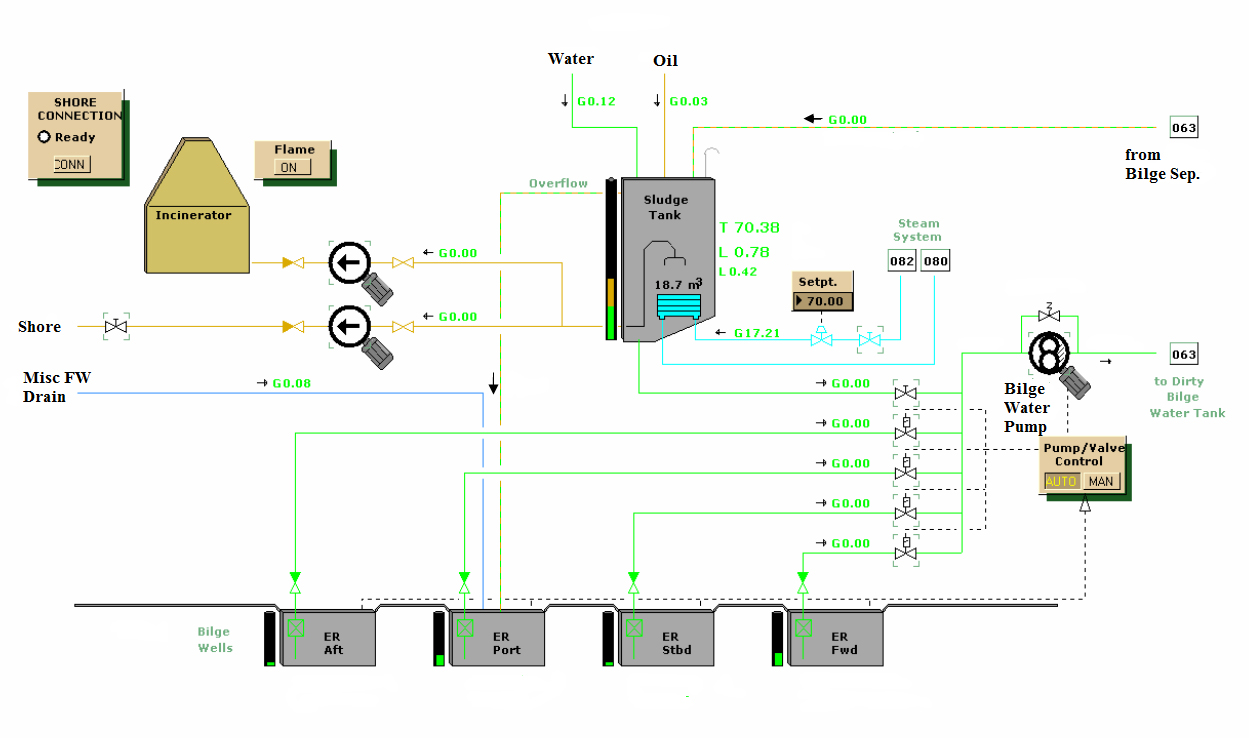

The separator is provided to eliminate engine room bilge water in accordance with current pollution prevention regulations by discharging water containing no more than 15 ppm of oil overboard.

The bilge separator separates oily water taken from the sludge tank or from the bilge wells. Clean water is pumped overboard or to the clean water bilge tank, while the oil is returned to the sludge tank.

The unit consists of a tank divided into several zones by internal baffles. A positive displacement bilge pump supplies unprocessed oil/water downstream into the separator and simultaneously discharge treated water out of the tank.

As the oil/water mixture flows through the tank, oil droplets is repelled under the influence of gravity and heat. Water passes around the beads but oil temporarily attaches to them. Oil droplets accumulate on the beads until they become large enough to break away to the top of the tank.

Meanwhile, the treated water is discharged from bottom of the tank, through the oil content monitor and then either overboard or to the Clean Bilge Tank, depending on residual oil content. Effluent will only be discharged overboard when its oil content is less than 15 ppm.

Eventually the oil layer at top of the tank increases sufficiently to trip a sensor which causes the separator drain solenoid to open. The accumulated oil is forced out through the oil discharge valve to the sludge tank.

If the separator is operated in “AUTO” mode, the following functions are automatic:

- The overboard valve is closed and the re-circulation valve opened if the ppm limit in the overboard water is above a pre-set limit.

- If the oil/water interface sensor detects low level (much oil), the sludge valve is opened.

- The bilge separator pump may be started/stopped automatically according to the bilge well level. This function is dependent on suction from the engine room bilge well.

A flashing AUTO light indicates functional failure. The cause can be high oil content (low-low oil/water interface level) or low separator temperature. The separator pump will then be stopped, the sludge valve opened and the overboard and recirculation valves closed.

The heating power is turned on/off according to temperature, by a thermostatic switch as long as the main switch is on. This switch works independently of the AUTO mode.

Figure 6.1.3.1 Bilge Separator (Lensevann separator)

Bilge Separator – Operation procedure

-

Preparation of bilge separator

1) Start electric heating of bilge separator and set separator operation in MANUAL.

2) Set the separator into AUTO mode when sufficient temperature (50ºC).

3) Check the setting of the ppm detector. -

Automatic or manual operation of the separator

Normally the separator is operated in AUTO. In Auto the valves for bilge over board, bilge re-circulation to clean bilge tank and sludge drain from separator to sludge tank are automatic controlled. -

Daily service bilge from engine rooms

1) Check oil content in bilge well.

2) Open suction valve from bilge well.

3) Open valves through separator.

4) Check that over board valve is closed.

5) Open discharge valve to clean bilge tank.

6) Check that the bilge separator is in auto.

7) Start bilge pump in manual.

8) If bilge has high content open 3-way valve before bilge separator and discharge directly to the sludge tank.

9) Let the oily water mixture separate in sludge tank before emptying water to clean tank. -

Automatic bilge from engine room bilge well

1) If AUTO control is active, the bilge suction valve from the engine bilge and the bilge pump will be activated according to the level in the bilge.

2) If the bilge pump is ON for more than 20% (adjustable) of the OFF time an alarm is activated. Immediate action must be taken. -

Emptying clean bilge tank

1) Check and note down time and ship's position.

2) Check that bilge separator is ready.

3) Open suction valve from clean bilge tank.

4) Open discharge over board.

5) Check that bilge separator is in Auto.

6) Start bilge pump.

7) Observe PPM-meter to avoid pumping oil overboard.

8) Check and note down time and ship`s position when finished. -

Stopping of the Bilge Separator

1) Ensure operation is in manual mode.

2) Close bilge suction valve and open sea suction to flush separator.

3) Manually open Sludge valve to remove recovered oil.

4) Stop pump and close sea suction and overboard valves. -

Bilge to shore

1) Check that shore connection has been established.

2) Note amount of bilge water in tank.

3) Open valves for bilge tank and discharge bilge ashore.

4) Start bilge pump.

5) Close valves before removing the shore connection.

6) Note and record amount of bilge discharged.

Note

Before discharge to shore remote stop of the bilge pump from deck location must be tested.

6.2 Bunkers operasjoner

Ved bunkring av skip er det viktig å unngå oljesøl, blant annet fordi dette forurenser det marine miljøet og kan utløse store bøter. Alle skip er derfor pålagt å ha godkjente prosedyrer om bord og å følge disse under bunkring.

6.2.1 Prosedyre for bunkring

All kommunikasjon under bunkring foregår normalt på engelsk. Et eksempel på standard anbefalt prosedyre for bunkring er derfor her gjengitt på engelsk.

Bunkering checklist

- Inform all the ships staff of the bunkering operation.

- Ensure all personnel are aware of the Emergency Response Procedures.

- Discuss the bunkering plan and tank sequence with officers involved.

- Close and secure all associated overboard discharge valves.

- Close and blank-off all unnecessary manifold valves/connections.

- Plug all deck scuppers and ensure they are oil- and watertight.

- Place oil absorbent materials at key locations.

- Provide a means of draining off any accumulation of deck water.

- Establish and check a common communications link between:

Bunkering Station, Duty Officer and Engine Room. - Check all bunker tank air pipes are open and unblocked.

- Ensure all sounding caps are tight when not being used.

- Reconfirm space remaining in all bunker tanks.

- Check all bunker tanks high level alarms are functioning.

- Ensure all fire precautions are observed.

- Check hose is of sufficient length.

- Inspect hose and couplings for damage.

- Check weight of hose is less than SWL of hose lifting gear.

- Place drip trays under hose couplings and flanges.

- Check delivery note quantity and specification are correct.

- Discuss bunkering plan with the supplier.

- Discuss vessels emergency response procedures with supplier.

- Discuss supplier`s emergency response procedures with ships staff.

- Establish communication link between vessel and supplier.

- Agree distinct signals for:

-Commence pumping for: _________________________ - Increase pumping rate for:__________________________

-Reduce pumping rate for: __________________________

-Cease pumping for: _______________________________ - Agree total quantity to be supplied. Specify: _____________

- Agree units of measurement- tons, cubic metres, etc. Specify: ___________

- Carry out spot analysis with vessels fuel test kit.

- Conduct compatibility test, if necessary.

- Sight, agree and record shore/barge meter readings or tank soundings.

- Rig fire wires, if required.

- Ensure seamen are assigned to tend moorings.

- Ensure a designated overflow tank is prepared, and lined up.

- Prepare (line up) the filling line-open all relevant valves.

- Commence bunkering at reduced rate.

- Monitor supply line pressure.

- Examine hose connections for leakage.

- Check all valves on the system.

FURTHER CHECKS DURING AND AFTER BUNKERING

- Check oil is entering the correct tank.

- Reduce pumping rate and/or open next tank before topping off.

- Close valves as each tank is completed.

- Witness, seal, date, jointly countersign, and retain bunker samples.

- Ensure sufficient ullage in final tank for hose draining/line blowing.

- Notify supplier when final tank is reached.

- Give supplier ample warning to reduce pumping.

- On completion, close all filling valves.

- Ensure all hoses are fully drained.

- Close and blank off manifold connection.

- Blank off disconnected hose couplings.

- Reconfirm all bunker tank soundings.

- Sight, agree and record shore/barge meter readings or tank soundings.

- Verify all details on the bunker receipts are correct.

Complete relevant entries in Oil Record Book and Log Books.

6.3 Ballastvann operasjoner

6.3.1 Krav til håndtering av ballastvann

For å hindre spredning av fremmede organismer via ballastvann og sedimenter er det innført krav til håndtering av ballastvann for alle skip.

IMO – BWM Convention (2004)

The Ballast Water Management Convention, adopted in 2004, aims to prevent the spread of harmful aquatic organisms from one region to another, by establishing standards and procedures for the management and control of ships ballast water and sediments.

Under the Convention, all ships in international traffic are required to manage their ballast water and sediments to a certain standard, according to a ship-specific ballast water management plan.

All ships will also have to carry a ballast water record book and an international ballast water certificate.

The ballast water management standards will be phased in over a period of time. As an intermediate solution, ships should exchange ballast water mid-ocean

Ballastvannforskriften

Nasjonale krav til håndtering av ballastvann er nedfelt i; Forskrift om hindring av spredning av fremmede organismer via ballastvann og sedimenter, gyldig fra 01.07.2010. Forskriften er i tråd med BWM konvensjonen.

Både BWM konvensjonen og Ballastvannforskriften er omfattende dokument og vil derfor ikke bli tatt med her.

Kort oppsummert går gjeldende krav ut på følgende:

- Utskifting av ballastvann skal skje i internasjonalt farvann.

- Ethvert skip skal ha om bord en plan for håndtering av ballastvann og sedimenter.

- Planen skal være spesifikk for det enkelte skip og inneholde en detaljert beskrivelse av hvilke tiltak og rutiner som skal treffes for å oppfylle kravene.

- Det skal fremgå av planen hvilke offiserer om bord som har ansvaret for at planen gjennomføres på en forsvarlig måte.

- Planen skal være godkjent i henhold til IMOs retningslinjer.

Videre er ethvert skip pålagt å ha om bord følgende:

- Ballastvanndagbok, og

- Ballastvann sertifikat.

Ovennevnte dokument kan lastes ned gratis på følgende nettsider:

BWM: http://maritime.about.com/od/Ports/a/Imo-Ballast-Water-Convention-Summary.htm

Ballastvannforskriften: http://www.lovdata.no

6.3.2 Ballastsystem

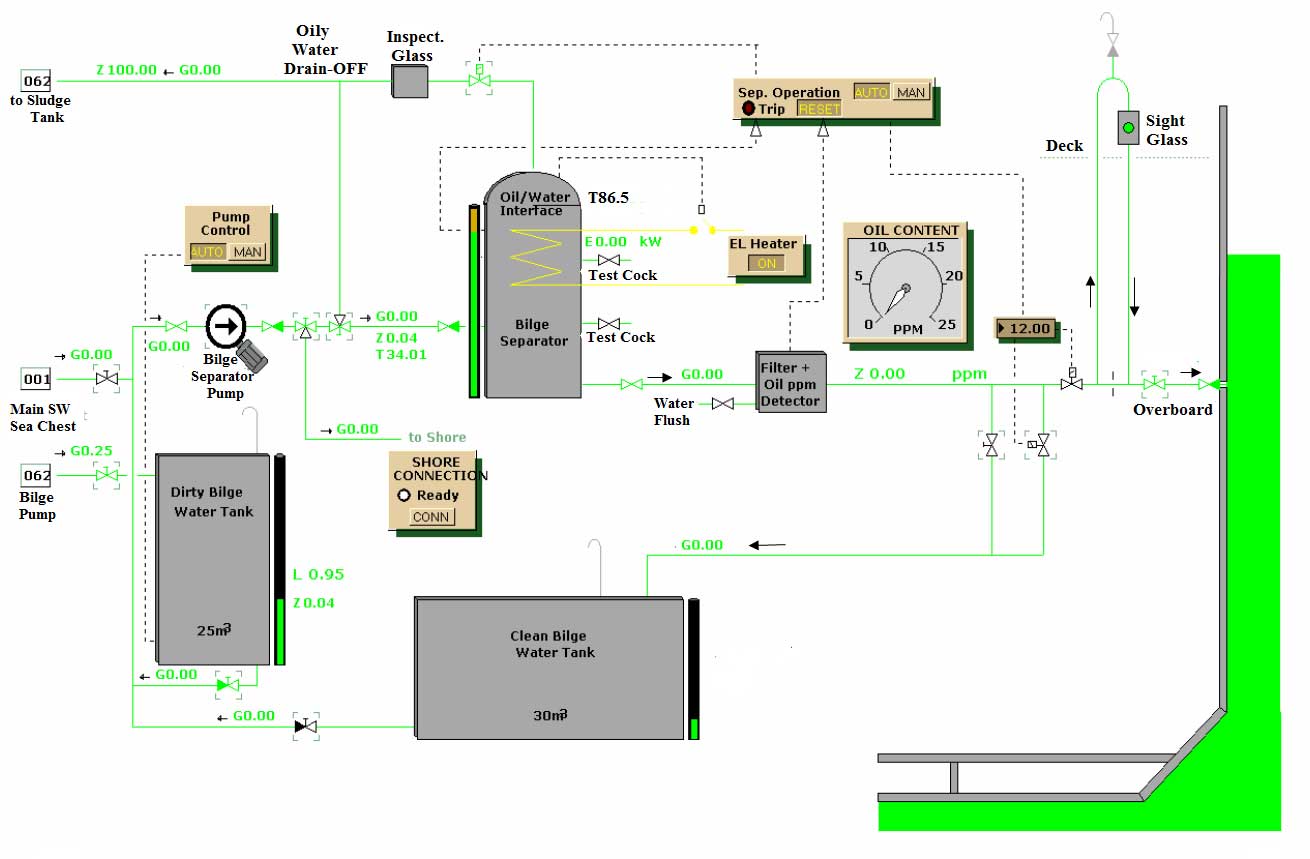

Figur 6.3.2.1 viser eksempel på et ballastsystem under en losseoperasjon.

Ballastturbinen skal bare kjøres når den oljefyrte kjelen er i bruk. Eksosdampen ledes til hoved kondenser.

En elektrisk drevet smøreoljepumpe blir brukt ved oppstart og en påhengt pumpe som sirkulerer smøreoljen ved vanlig drift. Etter pumpen strømmer smøreoljen via en ferskvanns kjølt varmeveksler før den blir levert til turbinen. To filtre er plassert i parallell, ett er i reserve «Stand-by».

Turbinturtallet er stillbart og dermed pumpens leveringstrykk. Ved å endre dette og reguleringsventilens åpning blir leveringsmengden justert etter behov.

Det er modellert et enkelt sikkerhetssystem for ballastturbinen. Turbintripp skjer ved:

- Rusing – for høyt turtall.

- Aksiell forskyvning av rotor.

- Lavt smøreoljetrykk.

- Høy smøreoljetemperatur.

- Høyt kondensertrykk.

Ved å trykke på reset – knappen tilbakestilles disse.

Start av ballastpumpen

-

Åpne følgende ventiler:

- Dreneringsventil på damp tilførselsledningen.

- Dreneringsventil på turbinhuset.

- Stengeventilen på tettedampledningen.

- Eksosventilen.

- Stengeventilen før smøreoljefilteret.

- Utløpsventilen på ferskvannssiden av smøreoljekjøleren. -

Start den manuelle smøreoljepumpen.

-

Stengeventilen(pådragsventilen) på damp tilførselsledningen åpnes sakte. Start med verdien 1, og øk sakte til verdien 20 i løpet av 5 minutter. Turbinens turtall vil øke jamt samtidig som rotor og turbin-hus varmes jevnt opp.

-

Når turtallet når 3500 o/min kan pådragsventilen åpnes helt og de to drensventilene stenges.

-

Turtallet til turbinen øker nå oppover til 6000 o/min (NB 6177 o/min på turbinen tilsvarer 1500 o/min på pumpen).

-

Følg med vannstanden og damptrykket på kjelen under belastning av ballastpumpen.

-

Pumpen fyller eller tømmer ballasttankene etter ønske. Legg merke til at ventilen foran ballasttanken kan regulere åpningen. Hvor hurtig ballast fylles eller tømmes kan således justeres til ønsket verdi. Skipets trim og krengning kan justeres vha. disse tankene.

-

Pumpens stige-ventil åpnes for å belaste pumpen.

STOPP av ballastpumpe

- Steng stige ventilen på pumpesiden gradvis.

- Steng alle ventiler for fylling/tømming av ballasttankene.

- Med en gang ballastpumpene har stoppet, steng pådragsventilen på damptilførselen sakte igjen til 0%.

- Start den manuelle smøreoljepumpen.

-

Åpne følgende ventiler:

- Drenventilen på tilførselsledningen.

- Drenventilen på turbinhuset. -

Steng følgende ventiler etter 5 minutt:

- Drenventilen på damptilførselsledningen.

- Drenventilen på turbinhuset.

- Stengeventilen på tettedampledningen.

- Eksosventilen.

- Stengeventilen før smøreoljefilteret.

- Utløpsventilen på ferskvannssiden før filtrene.

Steng ventilen på ferskvannssiden på smøreoljekjøleren.

Stans den elektriske smøreoljepumpen.

Figur 6.3.2.1 Ballast system